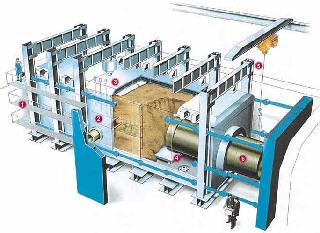

IKT’s Large Test Facility – as originally designed for pipe jacking

25 years ago, a hole was dug in the floor of our laboratory, this year we made it

bigger – why, you may ask? Well, it’s because this

Large (1:1 scale) Test Facility proved to be very adaptable for successfully comparing solutions to ageing sewer issues for sewer network owners. Extending it, as part of our current investment in improving existing facilities and construction of our

new Heavy Rain Lab, will provide

greater flexibility in addressing current and future issues – including accommodating test rigs for our current project on the

rehabilitation of pressure sewers.

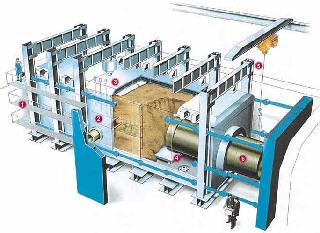

Making it larger

At 6m wide, 6m deep and 15m long this Large Test Facility was already the largest of its type anywhere. Now it has been extended by an additional 3m to 18m in length, across an area that was being used to insert jacked pipe segments. It is sealed against leakage to allow the simulation of loading on buried structures from rising groundwater and can simulate surface loads. Its use is focused on allowing underground infrastructure with simulated damage scenarios to be installed, buried, rehabilitated by various means under realistic conditions and for the performance of these technologies to be assessed against various loadings. Over the past 25 years this has included 1:1 scale evaluations involving re-creating main sewers, lateral sewers, lateral connections, manholes, and house connections. It has also been used to set out pipe networks for comparisons of CCTV inspection techniques and, during 2020, for comparing flowable backfills in simulated pipe trenches.

View within the facility of the new 3m extension to the wall

Now, completion of its extension to 18m and re-sealing means it is ready for installation of damaged pressure sewers in 2021 for our

current evaluation of their rehabilitation technologies.

Origin in understanding pipe jacking

The existing facility was built particularly with the evaluation of pipe jacking techniques in mind to guide the massive investment in new sewers in the surrounding region since the 1990’s. A series of experiments led to better understanding of how jacked segments actually behave when changing direction and the vital issue of joint performance under stress.

How well do patch repairs perform?

Project Steering Group considers 1:1 scale pipe layout to simulate house connections in the Large Scale Test Facility

The need for German sewer network owners to repair their own

small diameter sewers and advise property owners on their private connections led to this examination of how effective

patch repairs are in

sealing damaged pipes against groundwater. Changes in pipe material, diameter, damage scenarios and bends were included in test rigs buried in the Large Test Facility and changing groundwater pressures were applied. Whilst

effective repair is possible, special attention has to be paid to using the right product for some situations, like changes in pipe diameter.

Are flowable backfills really flowable and excavatable?

Our most recent project in the Large Test Facility required its division into five separate cells each simulating a pipe trench containing a range of manhole and pipe structures to investigate the performance of different flowable backfill material. There was a particular focus on whether the material would self-level, how quickly it could be walked on and built over, how well it supported the pipes and whether it could be subsequently excavated by hand. The results were surprising.

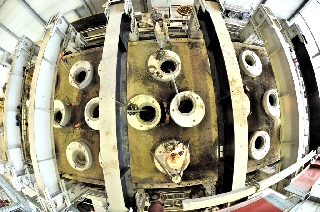

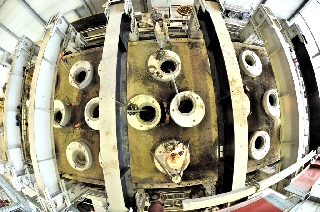

Performance of manhole rehabilitation technologies

Many manholes buried in the Large Test Facility

were installed into the Large Test Facility into which different products that are representative of available

rehabilitation technologies were installed. The experiment also included one new plastic manhole to examine whether it would float out as groundwater rose.

It was proven that it is possible to seal against ground water, but results were variable across the range of technologies. There was one complete failure of a product against groundwater pressure and various damages/imperfections observed in others. The vital necessity for good substrate preparation for products that bond to the wall and advice to wait until groundwater has risen before undertaking acceptance inspections were key findings.

How to seal damaged lateral connections

Project Steering Group members examine repaired lateral connects in the bottom of the Large Test Facility after excavation following exposure to rising groundwater pressure

The connections of lateral sewers to main sewer are a common cause of

groundwater infiltration so this project used the Large Test Facility to investigate how repair technologies could seal them in different situations:

- repairs to lateral connections in a CIPP lined sewer

- repairs to lateral connection in un-lined sewers

- laterals joining at different positions and angles

- repairs in pipe half-filled with water

The results ranged from good, to bad, to ugly.

Can lateral sewers be lined against infiltration?

Lateral sewers including material changes, damage scenarios and bends being installed for evaluation of liners

An

initial evaluation of lateral sewer lining systems against groundwater infiltration yielded an unexpected result – circumferential

cracking of the liners at the location of host pipe joints. The cause was determined to be that the

products bonded too tightly to the host pipe to be able to flex when pipe sections moved relative to each other due to floatation as groundwater levels rose. The industry made

modifications based on these findings, and satisfactory results were obtained for products submitted in a subsequent evaluation.

What are the limitations of CCTV inspection?

With so much reliance on CCTV inspection for mapping and monitoring condition of sewer networks this investigation in the Large Test Facility explored the extent to which:

- cameras could negotiate lateral connections, changes in diameter and bends,

- operators could identify damage scenarios, changes in pipe material and diameter,

- operators could produce a network layout plan.

The pipe networks were buried with access possible from manhole shafts. It was found that camaras could not reach all parts of the network and the accuracy of layout plans was not a good as expected.

Contacts

Want to learn more? Contact Iain Naismith!

phone: +44 (0) 7983 605219

email:

naismith@ikt.institute