Lining of Pressure Sewers: Evaluating One of the New Frontiers of Trenchless Technology

The issues with pressure sewers

For the past couple of decades sewer network owners and suppliers of liner technologies have been focused on addressing the rehabilitation of gravity sewers. For pressure sewers the focus has been on dig down and repair or excavate and replace. Pressure sewers are made from a range of materials, many are approaching the end of their service life or developing faults and there is an increasing requirement for rehabilitation, repair or replacement.

Trenchless rehabilitation techniques are usually the solution of choice for repairing damaged sewers, as they minimise disruption in the road and have economic and environmental advantages over open cut methods. However, sewer network operators cite a range of difficult issues for pressure sewers that limit the application and performance of trenchless solutions, such as lack of access points (for inspection or repair), bends up to 90°, unknown pipe layouts, and small nominal diameters in some cases.

Although the first rehabilitation techniques for sewage pressure pipes are now being offered on the market, sewer network owners have realised there is a considerable need to investigate their applicability and limitations. On the one hand, there is a lack of neutral and independent information on installation requirements, application range, performance and application limits of the available processes and products. On the other hand, there is currently very little experience to draw on when considering rehabilitation measures for pressure sewers.

Investigation the applicability and limitations of the first rehabilitation techniques for pressure sewer pipes

Achieving the objectives

The objective will be achieved through comparative evaluation of the techniques available in the market. Working with the project steering group of sewer network operators, the typical damage scenarios encountered with pressure sewer pipes are being defined and a testing concept developed.

What is available?

A market review of available technologies, products and suppliers is being undertaken and, from this, the project steering group will be selecting eight products for evaluation that are representative of the available technologies. This review is also considering the current status of applicable standards and regulations.

Evaluation

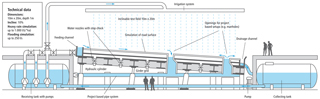

1:1 scale laboratory testing is being devised that will result in test rigs being installed in IKT’s large-scale test facility comprising pumped pressure pipes in which typical damage scenarios have been created.

The selected rehab products will be installed and tested under identical conditions which will include assessing their ability to withstand the typical pressure changes experienced in live pressure sewers. To support the laboratory evaluation, in-situ evaluation will be undertaken on the same techniques installed in sewer pressure pipes at the network operators’ sites. In addition to their performance the quality assurance provisions for the products will be evaluated.

IKT Compare tests

On-site installation conditions simulated in IKT’s large-scale test facility – here with manholes to test and compare rehabilitation methods

Test subject matter, procedures and criteria are defined by the respective steering committee. Decisions concerning the final evaluations are also taken jointly by the network operators in these supervisory bodies. This ensures that the tests are performed on a strong practical basis, impartially, and without any influence from commercial interests.

The aim

The results provide the network operators with well-founded, dependable information on the strengths and weaknesses of the products and procedures available on the market. This then enables them to base their purchasing decisions on solid facts, rather than solely on the manufacturers’ advertising. IKT’s product tests at the same time provide the various suppliers with indications for the improvement of the products and procedures tested, and thus also for the strengthening of their market position. Ultimately, these are all benefits for the entire industry.

Find out more:

IKT Compare

IKT Compare project results

IKT has done research on inspection and condition-surveying of pressure sewer lines. Now the focus is on rehabilitation.

As with all IKT Compare projects the members of the Project Steering Committees additionally benefit from the exchange of knowledge and experience with other network operators.

Additional partner projects

Core funding for this project has been provided by the Ministry of the Environment of the State of North Rhine-Westphalia, and supported by the participating German sewer network owners. A partner project alongside this main project in Germany is being undertaken with the City of Arnhem, The Netherlands, to examine pressure sewer inspection techniques. Another partner project is in development with sewer network owners from other countries that will include consideration of the application of lining to larger diameter pipes.

If you are a sewer network owner and would like to find out more about the project or consider joining a partner project please get in touch.

Contacts

- Dipl.-Ing. Markus Gillar

IKT Senior Research Fellow

phone: +49 209 17806-46

email: gillar@ikt.institute - Dipl.-Ing. (FH) Serdar Ulutaş, MBA

IKT Senior Research Fellow and Head of IKT Compare

phone: +49 209 17806-32

email: ulutas@ikt.institute - UK: Dr Iain Naismith

phone: +44 (0) 7983 605219

email: naismith@ikt.institute