30 Years of Sewerage Research at IKT – Institute for Underground Infrastructure: What was, what is and what is yet to come

Initial investigations using camera inspection technology, which was still quite new at the time, showed that the structural condition of urban wastewater pipes was very problematic in many places. Pipes were leaking, they were hydraulically restricted and their structural fabric was under attack. The necessary funding for this was estimated to be in the high billions.

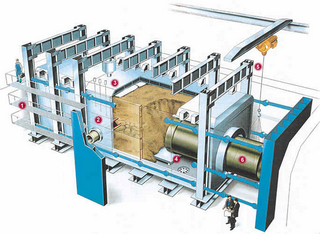

Large-scale testing at a real, 1:1 scale

The idea of IKT’s founding fathers was to explore and support this high need for rehabilitation with practically orientated solutions research and material testing. Systems and technologies for underground construction were to be researched and tested on a 1:1 scale in an institute specially created for sewerage technology.

They designed a large-scale test rig for this purpose, the likes of which had never been seen anywhere in the world before. It was to be used to simulate construction sites on a 1:1 scale, with everything that goes with it: soil structure, groundwater, soil pressures and traffic loads. Everything that exists on sewer construction sites was to be realistically constructed. The facility should enable open and trenchless construction methods, including the latest tunnelling and rehabilitation techniques.

Financial support from Ministry of the Environment

The concept met with great approval from municipal sewer network operators as well as construction companies and product manufacturers. The founders turned to the North Rhine-Westphalian Ministry of the Environment for the necessary funding.

The ministry recognised the potential of such an institute, particularly for groundwater protection, because leaking and blocked wastewater pipes endanger the environment. The Ministry therefore provided a large proportion of the funding for the construction of the institute.

Foundation in Gelsenkirchen

The institute was founded as a non-profit limited company based in Gelsenkirchen. The initial shareholders were a development association and the city of Gelsenkirchen. After a planning and construction phase of just two years, which is very short by today’s standards, IKT began operations thirty years ago, in autumn 1994.The management team consisted of Prof Dr Dietrich Stein as Scientific Director and Felix Weddige as Commercial Director. They were supported by Dr Christian Falk as Scientific Manager. The Supervisory Board and a Friends’ Association were first headed by Dipl.-Ing. Jürgen Wilms and shortly afterwards by Dr.-Ing. Rolf Bielecki. From a handful of employees at the beginning, the IKT has now grown to 50 employees.

State-of-the-art testing technology

A large research hall was built for the extensive testing technology. The large test stand alone has impressive dimensions: made of steel, 18 metres long, six metres wide and six metres high, it is still the experimental heart of IKT today.

There is also an elastomer and an electronics laboratory as well as two gantries with large pressure cylinders for dynamic and static load tests with which earth and traffic loads of up to 4000 kN can be simulated.

First successes

In its first five years, IKT initially focussed on research into geophysical subsoil exploration, pipe jacking, sewer gasses, infiltration and tree root ingrowth. The Institute also took up the topics of pipe and manhole rehabilitation at an early stage.One ground-breaking project was the first to scrutinise sewers that had been rehabilitated with pipe liners. Sections of pipe that had previously rehabilitated with Cured In Place Pipe (CIPP) 5 to 15 years earlier were excavated from the networks of several municipalities and thoroughly analysed.

The results revealed the entire spectrum of the installation quality issues with pipe lining. They attracted a great deal of attention from experts and laid the foundation for subsequent work focus on the quality of sewer rehabilitation, which IKT continues to pursue intensively in numerous projects to this day.

Prof. Dr.-Ing. habil. Bert Bosseler, Scientific Director of the IKT, and Roland W. Waniek, IKT Managing Director (r.)

New management

As successful as the scientific research was, the business side of the initial phase was difficult.

With the economist Roland W. Waniek appointed as Managing Director (1999) and the civil engineer Prof. Bert Bosseler appointed as Scientific Director (2000), a new management team took over responsibility. Together, they and the entire team worked together to devised a new strategy.

New strategy

The core idea behind this reorganisation of the Institute was and still is to move away from purely academic research towards addressing the practical questions and issues faced by municipal network operators. This is because they are locally responsible for the construction, operation and renovation of underground networks. They decide which technologies they use, which investments they make and how they operate their networks. Therefore their needs made them the target client group for IKT activities.

The “informed network operator”: IKT consistently aligns activities with the knowledge requirements of network operators.

In addition, the Institute was renamed IKT – Institute for Underground Infrastructure to signal that it not only deals with sewerage systems, but also with other pipeline networks.

New shareholder structure

The new strategy also required a new shareholder structure. The city of Gelsenkirchen left as a main shareholder and was replaced by the newly founded IKT-Förderverein der Netzbetreiber e.V., to which more than 150 municipal drainage companies now belong. Any public sewer network operator can become a member. The association holds two thirds of the shares and therefore has a majority stake in the non-profit organisation.

The voice of sewer network operators: IKT Association of Sewer Network Operators is the majority shareholder of IKT

However, because it is not only the demand side of the professional world that is important, but also the supply side with its expertise, the second IKT shareholder is the IKT-Förderverein der Wirtschaft e.V. (IKT Industry Association). More than 60 companies from the private sector belong to this organisation: manufacturers, engineering offices, rehabilitation and construction companies, primarily from Germany, but now also from countries such as Belgium, China, Japan, the Netherlands and Switzerland.

That association holds a third of the IKT shares and its function is to gather issues relating to the supply side of the industry and incorporate them into the Institute’s work. Any interested company can become a member.

New business areas

The traditional field of research was initially expanded at the beginning of the century to include three new business areas: comparative product testing, material testing and consulting. Later, training, flow measurement and managing the municipal network of wastewater companies – KomNetABWASSER – were added.

Comparative product tests

The product test projects in particular have cemented the IKT’s reputation as a neutral and independent institute. This is particularly important for supporting investment decisions by local authorities. With its comparative product tests, the Institute analyses the strengths and weaknesses of marketable products and processes. More than a dozen major product test projects have been completed to date, including on house connection repairs, manhole renovation, flow restrictors, liquid soil trench backfill and the renovation of pressurised wastewater pipes. Download here: All IKT product test reports

Two above, one below: The IKT testers distributed the damage across a small house connection network.

Municipal steering committees

A local steering committee is formed for each product test project, which determines which products are tested, what the test programme looks like and what criteria are used for evaluation. The IKT large-scale test rig is usually used for the test set-up.

This enables IKT scientists to simulate sewer situations and construction sites on a 1:1 scale. Sewer pipes, manholes and special structures are installed and damage scenarios are realistically applied, before rehabilitation is undertaken by manufacturers and contractors using their respective products and processes.

Supporting investment decisions

In the test rig, long-term operational loading is simulated, such as traffic loads, high-pressure cleaning and changes in groundwater pressure. IKT scientists examine the remediation results and report to the municipal steering committee. The steering committee then evaluates and grades the products. The results are widely publicised so that all municipalities can use them to support their investment decisions.

Testing laboratory for building products

IKT operates two testing laboratories for material and construction product testing. Both are recognised by the German Institute for Building Technology (DIBt).

On the one hand, there is a focus on testing CIPP liner samples that are taken at installation sites and checked for watertightness and material characteristics. The test results show clients whether they have actually received the promised installed quality. All test results are published in tabular summaries in the annual IKT Liner Report.On the other hand, tests are carried out on treatment plants for wastewater, such as decentralised rainwater treatment plants or oil separators. In this way, manufacturers, customers and operators find out whether products fulfil the requirements and learn about the efficiency of the treatment.

IKT Managing Director Roland W. Waniek (left) hands over the seal to Managing Director Christoph Erdbrügger from the Erdbrügger Group.

Here you can see how IKT operates its scheme of seals from product tests and test projects.

Due to increased heavy rainfall and because rainwater is to be infiltrated and stored, the testing centre has already extended its accreditation to infiltration products. All DIBt approval tests required for this can now be carried out at the IKT.

Ongoing training for practitioners

Part of the strategic reorientation is to pass on the knowledge acquired in research and product testing to the entire industry. To this end, IKT offers a varied programme of more than 120 seminars, workshops, courses, in-house training sessions and congresses.

The topics are closely coordinated with municipal network operators and cover what is important to them. This includes classic technical content on construction, renovation and operation. But the programme also includes courses on heavy rain consultancy, sewer management and regulation. Even “exotic” topics such as rat control are included. Those who pass the courses are rewarded with an IKT certificate.

Municipal network of wastewater companies

The IKT’s focus on the issues and problems of sewer network operators is particularly reflected in the municipal network of wastewater companies – KomNetABWASSER. The Institute launched this network in 2008, initially focussing on the topic of citizen advice for private property drainage.

In the meantime, the range of topics has expanded considerably. It encompasses all technical and operational issues relating to urban drainage. Over the years, a strong community of wastewater companies has developed, providing mutual support and encouragement. They exchange ideas with their peers from other municipalities, ask questions and get useful answers to sopport their own work. More than 170 municipalities across Germany are now members of KomNetABWASSER.

The network attaches great importance to continuous further training. All employees of participating municipalities can attend all IKT seminars free of charge. They also receive technical advice and materials to support their public relations work.

International orientation

IKT is very aware that the issues faced by network owners are very similar around the world, that there are lessons to learn from each other and that its research has applications internationally. So, IKT is becoming increasingly internationalised in terms of its staff, its clients, its outreach and translation of its reseach reports. Starting in 2013, the Institute has been operating a pipe liner laboratory for the Benelux region in the city of Arnhem in the Netherlands. Training courses and research are also offered there.

IKT has an office near Oxford for the UK. British network operators are advised there primarily on issues relating to sewer rehabilitation. The Institute’s overseas activities are also coordinated from there. These include international research projects and seminars.

European Laboratory Network

IKT has been part of a large European laboratory network for four years. Under the name “Consortium of Drainage Laboratories (CoUDLabs)”, renowned water researchers from seven countries have joined forces to address future issues of climate-resilient urban drainage. This network is funded by the European Union.

New investments in testing laboratory and heavy rain research

Shortly before its 30th anniversary, the IKT has extensively expanded its test laboratories. Investments have been made in state-of-the-art test rigs and equipment that significantly expand the range of services.

This means that a wider range of construction products can now be subjected to dynamic and temperature loads. State-of-the-art and novel materials can be tested for behaviour, durability and operational stability. With UV test and weathering systems, it is now also possible to analyse plastic products for above-ground infrastructure.

NRW Environment Minister presents the multi-million euro funding decision to IKT Managing Director Roland W. Waniek and the Scientific Director of IKT, Prof Dr Bert Bosseler.

These new and expansion investments totalling millions are financially supported by the EU, the state of North Rhine-Westphalia, Emschergenossenschaft/Lippeverband, GELSENWASSER and Abwassergesellschaft Gelsenkirchen.

Urban drainage agenda 2035

This makes it clear that even after 30 years of sewerage research, there will still be more than enough to do. IKT and its partners will certainly not be bored. The next ten years will be particularly challenging for urban drainage systems.

A good reason for a generous calorie intake: the IKT celebrated its 25th anniversary five years ago.

The German “Agenda Urban Drainage 2035” congress (10th/11th September 2024) will be focusing on what German urban drainage systems will increasingly be facing in the next ten years: sewer renovation, climate adaptation, AI and capacity bottlenecks.

The International Conference (11th/12th September 2024) will be hearing about the issues affecting sewerage and urban drainage in different countries and some of the solutions being adopted and reserched.

Attendees from both Conferences have the opportunity to come together and celebrate IKTs 30 years at an evening birthday party on 10th September – be there too!

IKT Congress “Agenda Urban Drainage 2035”

10 – 11 September 2024

Programme and registration here: Congress with anniversary celebration

IKT 30 International Conference

11 – 12 September 2024

Contact: naismith@ikt.institute