Test Centre for CIPP liners

The IKT Test Centre is a supervisory body for CIPP liners and short-liners and is recognised by the German Institute for Construction Technology (DIBt). It is accredited to European Standards (DIN EN ISO/IEC 17025) for selected mechanical and technical tests on polymeric components of pipe and CIPP liner systems and samples of GRP laminate.The IKT Test Centre thus fulfils the requirements for the performance of materials tests in accordance with ZTV Materials Testing (CIPP liner test standards), DWA-M 144-3 and DWA-A 143-3.

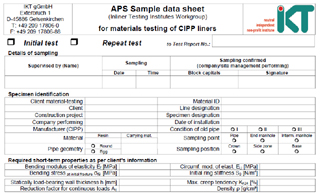

Sample data sheet

Materials testing of CIPP liners

Please enclose this form when you send us your samples. This ensures that your sample can be correctly identified.

Please complete a sample data sheet for each individual site sample you send us.

Sample data sheet for CIPP liners

Site sample

- What must be the dimensions of a site sample?

- What else is important?

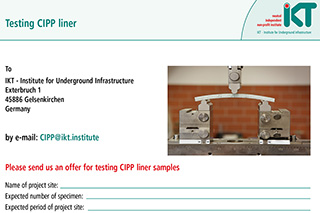

Request for quotation

Materials testing of CIPP liners

Do you require standard or expanded-scope tests?

We will provide a quotation tailored to your needs, to ensure that your QA requirements are met.

Request for quotation CIPP liners

Accredited Quality Assurance

Unlike factory-finished pipes, CIPP liners attain their ultimate geometrical and mechanical properties only after in-place curing at the installation site. The quality of the work performed on site is thus critical for the quality of the end product.

To address this issue, the tests explained in more detail below are required in ZTV Materials Testing (CIPP liner test standards) as well as DWA Code of Practice 144-3 and DWA Standard 143-3 for quality assurance purposes.

IKT is an accredited test and supervisory body recognised by the German Institute for Construction Technology (DIBt) for the performance of tests on CIPP liners and plastics.IKT tests samples of CIPP liners taken on-site impartially and independently on behalf of project clients. The test report documents in detail whether the required quality criteria have been achieved.

The institute publishes its IKT LinerReport each year detailing the performance of both liner systems and contractors.

Overview of test and inspection criteria

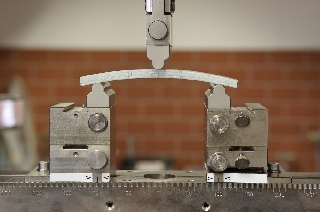

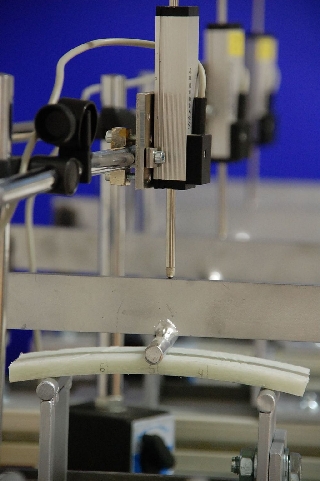

Modulus of elasticity (short-term flexural modulus)- CIPP liners must be capable of withstanding loads such as those arising from groundwater, road traffic and soil pressure

- The modulus of elasticity is an indicator of load-bearing capability

- Stability may be endangered if the modulus of elasticity is too low

- Test method: Three-point bending test as per DIN EN ISO 178 and DIN EN ISO 11296, Part 4

Flexural strength (flexural stress at rupture)

- This indicates the point at which the liner fails due to excessively high stress

- If flexural strength is too low, the liner may rupture before the permissible deformation is reached

- Test method: Increase of load up to failure in the three-point bending test in accordance with DIN EN ISO 178 and DIN EN ISO 11296, Part 4 (short-term flexural strength)

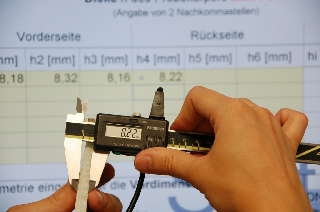

Wall thickness (mean combined thickness)

- Minimum values are specified in the structural-analysis calculations for liners

- Wall thickness and modulus of elasticity jointly determine the stiffness of the liners

- Excessively low wall thickness can endanger stability

- Test method: Mean combined thickness is measured in accordance with DIN EN ISO 11296, Part 4 using a precision slide gauge

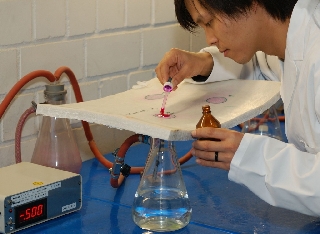

Water tightness

- A cut is made into the inner film if the latter is not an integral component of the liner; the outer film (if any) is removed

- Water containing a red dye is applied internally

- A 0.5 bar partial vacuum is applied externally

- The liner is “Not tight” if water penetrates through

- Test period: 30 min.

Glass transition temperatures (DSC analysis)

- This indicates the curing of epoxy resin, e.g. in sewer-lateral liners

- If the glass transition temperature is too low, the resin is not cured completely

- The temperature can be determined using a small sample of 20 mm cross-section

- It is determined if it is not possible to take a sample for mechanical testing

Expanded-scope tests

The minimum scope of testing for CIPP liners consists of the three-point bending test for determination of modulus of elasticity and bending stress, and the water tightness test.Further tests are available, as defined in the ZTV Materials Testing for CIPP liners specification, which make it possible to determine the quality of CIPP liners even more precisely.

They include:

- Spectral analysis

- Determination of trace styrene content

- Determination of filler material and glass content

- 24 hr creep

- Density

The importance and benefits of these expanded-scope tests for the project client are explained in detail here:

Overview of expanded-scope CIPP liner tests

Contact

Dieter HomannDipl.-Ing.

T: 0209 17806-24

E: homann@ikt.de

Contact:

IKT - Institute for Underground Infrastructure

neutral, independent, non-profit

T: +49 (0) 209 17806-0

E: info@ikt.de

www.ikt.de

www.facebook.com/IKTonline

www.youtube.com/IKTonline