Concrete, component and method tests

Products subject to mandatory technical approval are required to undergo strict quality monitoring. IKT, as an officially designated test, monitoring and certification centre, validates the following, for example:- Pipes

- Manholes

- Special shapes

in concrete, reinforced concrete and vitrified clay, including the associated pipe joints and sealing elements and agents.

IKT also acts as a test centre for the “Güteschutz Beton NRW” (BGB) concrete quality assurance organisation.

Self- and third-party supervision

IKT test centre offers its customers the following services for self- and third-party monitoring to European Standards:- Concrete pipes, reinforced-concrete pipes, and shapes

DIN EN 1916 and DIN EN 1201 - Concrete and reinforced-concrete prefabricated manholes/manhole components

DIN EN 1917 and DIN V 4034 - Elastomer sealants

DIN EN 681 and DIN 4060 - Paving stones

DIN EN 1338 - Paving slabs

DIN EN 1339 - Kerbstones

DIN EN 1340 - Surround stones and water-permeable paving stones

BGB code for non-standardised concrete products

Large and diverse range of tests possible

Deformation of manhole joints under vertical compressive load

- Elastomeric pressure-transmission elements

- Vertical deformation under dynamic traffic loads is a vital factor

in accordance with the DIN V 4034, Part 1 manholes standard. - Deformation behaviour of pressure-transmission elements during pipe jacking as specified in accordance with DWA Standard A161

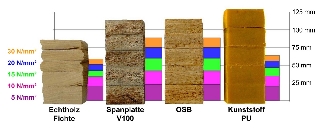

- Determination of sealing width, contact pressure distribution and maximum deformation

- Knowledge of contact pressure distribution is important for the development of sealing sections and of pipes

- Measurement by means of pressure-sensitive films

- in accordance with DIN EN 1916

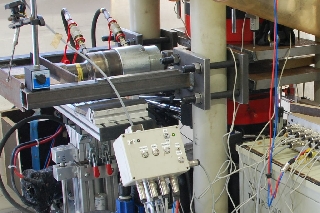

- Injection tests on the medium-format test stand

- Injection tests for the repair of sewer laterals

- Checking of tightness against extraneous water by means of flooding of the test stand

- Service-life two months

- Tests on buried conduits

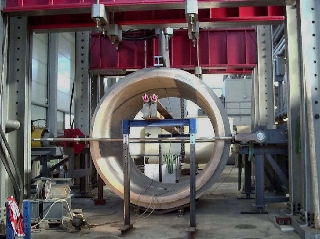

- Vertical and horizontal test forces are transmitted into a pipe simultaneously

- Highly authentic moment/normal force loads

- Actual cracking performance is reliably simulated

- Important for the assessment of crack widths and crack lengths in on-site acceptance inspection of large-calibre pipes

- Measurement of water uptake

- Visual checking of tightness

- Test pressures up to 2.5 bar

- in accordance with DIN EN 1916 and DIN EN 1201

- Exposure to vertical compressive loads

- Measurement of crack widths

- Measurement of ultimate compressive strength

- Checking of concrete cover and reinforcement

- in accordance with DIN EN 1916 and DIN EN 1201

- Tightness testing under shearing load in the pipe joint

- Visual checking of tightness

- in accordance with DIN EN 1916 and DIN EN 1201

- Bending load in the pipe-length direction

- Taking account of inadequate support

- in accordance with DIN EN 1916 and DIN EN 1201

- Quality Assurance for finished components and in-situ concrete

- in accordance with DIN EN 12390

- Checking of dimensional tolerances

- Also important for tightness

- in accordance with DIN EN 1916 and DIN EN 1201

- Resistance of external coatings

- Suitability for trenchless installation methods

- No applicable standards

- Low-shear-resistance pressure-transmission elements increase the load acting on the pipe joint

- Shear strains as a function of jacking loads

- Fundamental research

- Fluid-conducting line with radiant heat loss

- Effects on sheathing pipe often neglected

- Long-term investigations on buried sheathing pipes

- Expansion of fibre-optics networks necessary

- Installation of the “last mile” also in the pavement

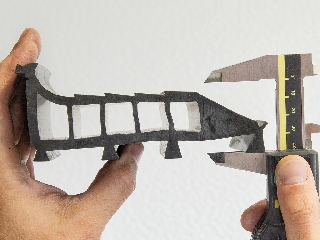

- Splitter water-tightness important!

- Analysis of suitability of splitters for buried installation

- Dieter Homann

Dipl.-Ing.

Director Material Testing

T: +49 (0) 209 17806-24

E: homann@ikt.de - Martin Liebscher

Dipl.-Ing.

T: +49 (0) 209 17806-23

E: liebscher@ikt.de

Pressure-transmission elements for pipe jacking

Sealing width of elastomeric sections for concrete and reinforced-concrete pipes

1:1 scale method tests

Modified vertical-compression test on large-calibre pipes

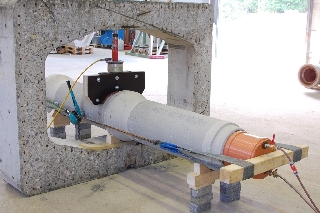

Tightness testing of DN1600 jacking pipes

Tightness testing of a pipe string: DN1600, reinforced concrete, length 11 m, filled with 22 m³ of water and pressurised to 10 m w.g.

Vertical-compression tests on DN1600 jacking pipes

Shear-load tests on DN300 pipes

Determination of longitudinal flexural strength on DN300 pipes

Strength in compression of concrete cubes

Measurement of concrete and reinforced-concrete pipes

Determination of external abrasion on cast pipes

Shear strain of pressure-transmission elements under exposure to vertical and horizontal loads

Measurement of temperature in buried sheathing pipes

Tightness testing of buried fibre-optics splitters

Contact

Contact:

IKT - Institute for Underground Infrastructure

neutral, independent, non-profit

T: +49 (0) 209 17806-0

E: info@ikt.de

www.ikt.de

www.facebook.com/IKTonline

www.youtube.com/IKTonline